Duct winding machines for manufacturing rigid folded spiral ducts made of steel & stainless steel

HAFLEX · The specialist for duct winding machines

HAFLEX products for companies

in the field of air-conditioning & ventilation technology

You can now manufacture your own flexible ducts easily and economically

Flexible ducts are used in the field of air conditioning and ventilation technology. Flexible ducts are often used here because, unlike rigid ducting, they can be easily adapted to the structural conditions on site. Tight spots, bends and sharp curves do not cause any problems for flexible ducting. Ideally, flexible ducts used in central ventilation systems are corrugated on the outside and smooth on the inside so that dust cannot accumulate and they are easy to clean.

You can manufacture these flexible ducts yourself with HAFLEX duct winding machines; in your warehouse, in your own workshop or even in a vehicle on site! Flexible ducts made with HAFLEX duct winding machines lead the way in terms of technology and quality and set the standard in markets worldwide. They are extremely elastic and pliable, which makes them very flexible. The flexible duct can not only be compressed to its minimum size, but also extended to its maximum length. In this way, it adapts very well to suit the building’s requirements.

HAFLEX products for companies

in the field of air-conditioning & ventilation technology

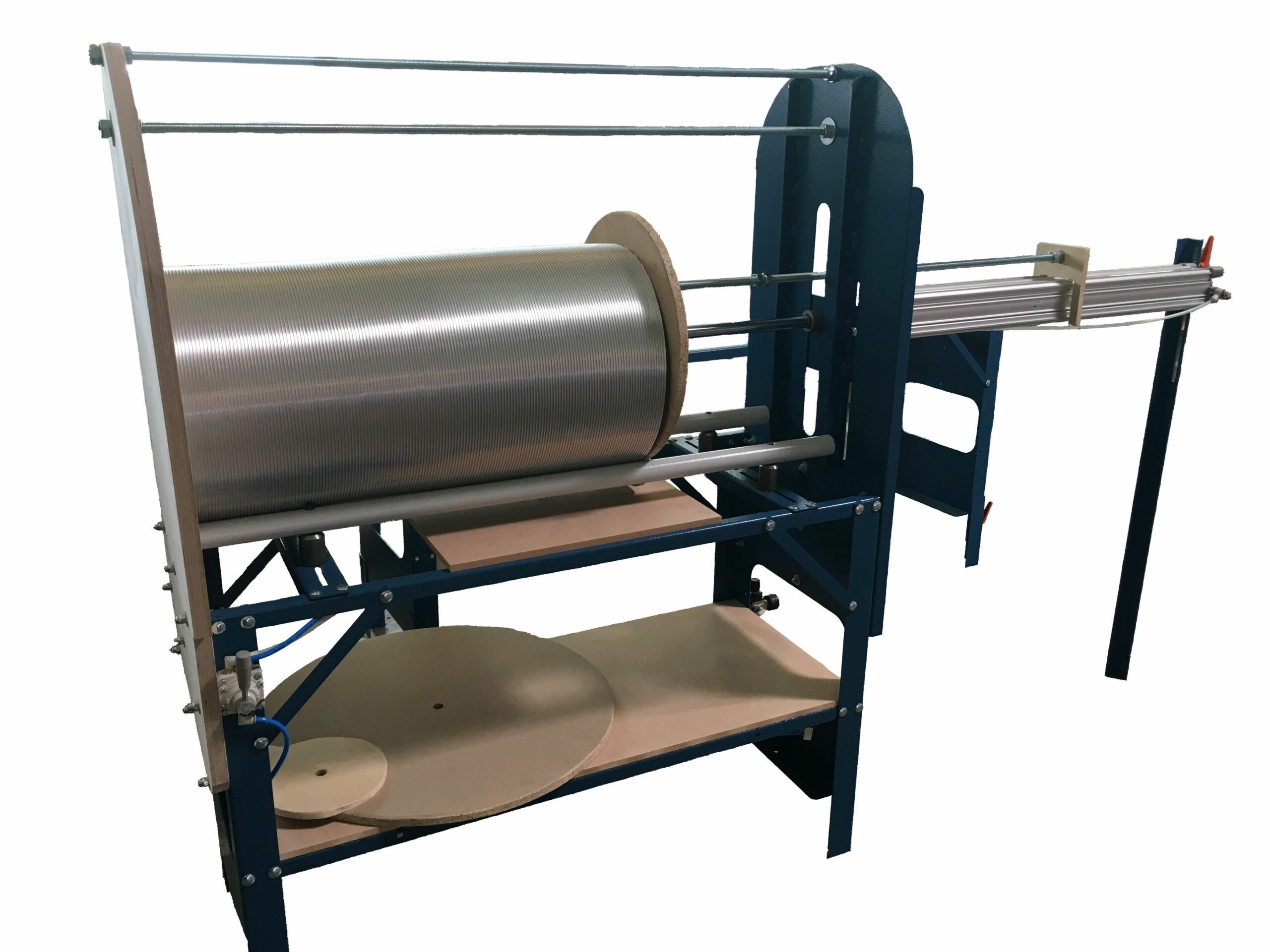

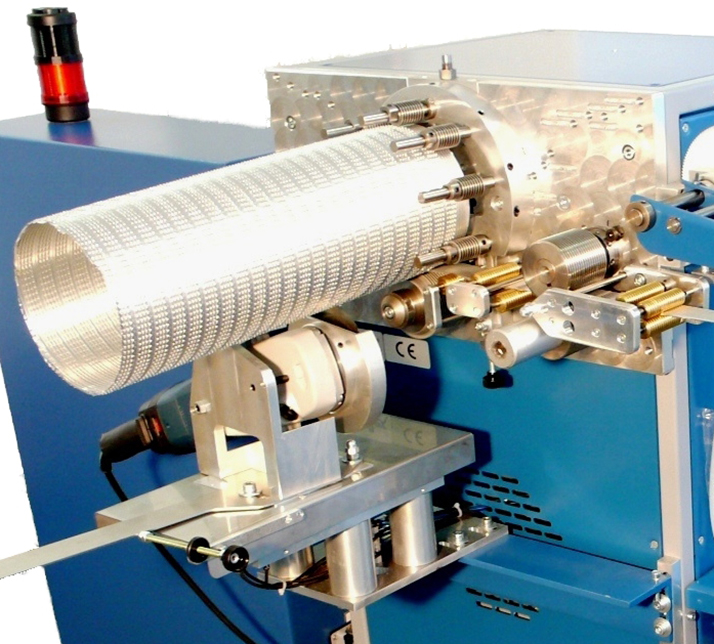

HSW 992A duct winding machine for manufacturing flexible hoses and compressed ducts for air-conditioning and ventilation technology.

+ Air ducts 50–650 mm (2 – 25”) according to DIN EN 13180

+ Highest quality with pre-profiled precision strips made of aluminium, stainless steel, galvanised steel

+ Strip thicknesses from 0.04–0.15 mm

+ Compact and economical machine

+ Simple operation

+ Very high production speed

+ Patented folding joint

+ Ducts made of aluminium, galvanised steel and stainless steel

+ Economical due to the use of thin strips

+ Conversion kits for producing aluminium silencers, galvanised steel rigid ventilation ducts and stainless steel chimney liner ducts

Video duct winding machine HSW 992A

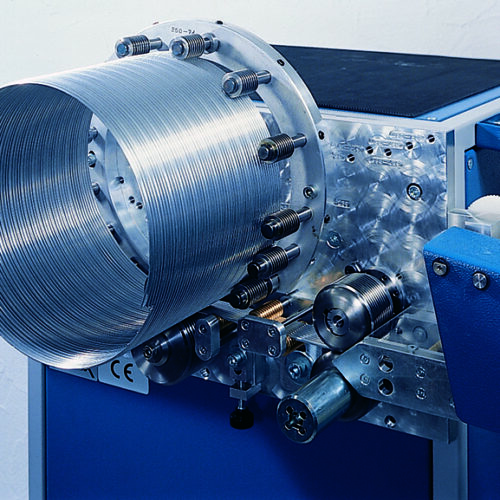

HSW 904G duct winding machine for manufacturing flexible two-layer internally smooth ducting.

+ Air ducts according to DIN EN 13180 have special hygiene requirements: easy to clean flexible ducting.

+ Low friction resistance

+ Highest quality with pre-profiled precision strips made of aluminium, stainless steel, galvanised steel

+ Strip thicknesses from 0.07–0.12 mm

+ Inner and outer wall can be made of different materials and strip thicknesses

+ Conversion kits for producing flexible corrugated hoses, aluminium silencers, flexible stainless steel chimney liner ducts and rigid galvanised steel ventilation ducts

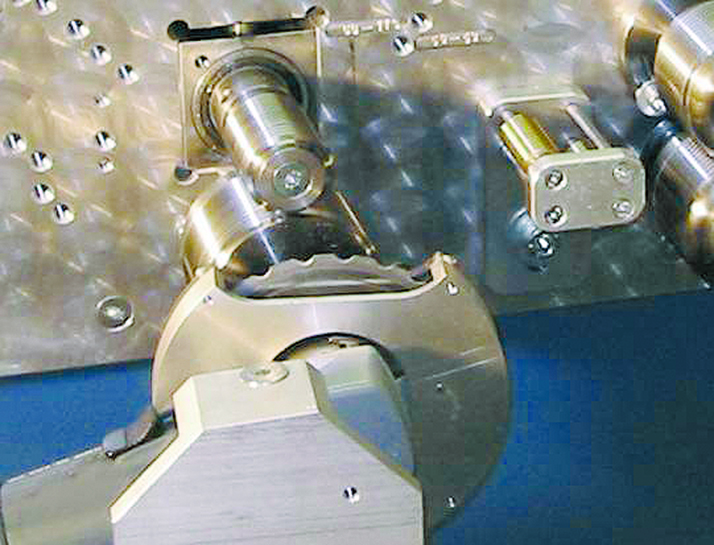

Conversion kit for producing telephony silencers.

+ Produce on 992A, 992S and 904G machines with the conversion kits for perforated inner ducting.

+ Outer duct made of aluminium, galvanised or stainless steel.

+ Perforated aluminium inner duct, choice of insulation.

+ Diameter range 80–300 mm

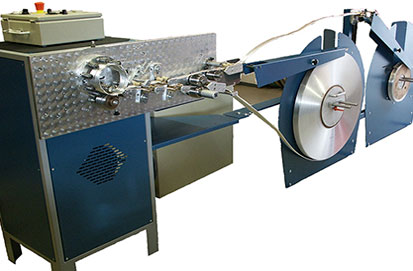

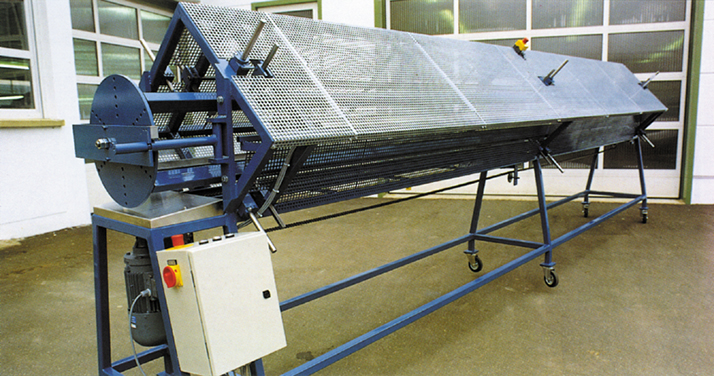

HAS 500 automatic saw for automatic cutting of flexible aluminium hoses.

+ Cut while duct is running.

+ Nominal widths 50–650 mm.

+ Incl.: 5 m long special duct guide and storage table

+ Cutting lengths ranging from 1 to 5 m

Automatic cut length control: The machine is slowed down to the optimum speed for cutting at the first light barrier. Simultaneously, a pneumatically actuated disc brake is applied to the coil to prevent it from overrunning.

The second light barrier triggers the sawing process. A special saw blade cuts without any chips, keeping the duct and the rollers clean. When the cutting process is complete, the cut duct is ejected into the chute and the machine accelerates back up to working speed.

A counter registers the number of cuts made so that the required number of cuts can be pre-set. Detectors stop the machine when the coil is empty or when the chute is full. Saw stroke and duct ejection are carried out by pneumatic cylinders. Customer requires air connection for 5 bar dry air. Incl. safety device: the saw stops automatically if an unauthorised person approaches the sawing area. More information available on request.

Video automatic saw

Video saw compression machine

Video automatic saw & compression machine

HST 650 A5 compression machine for compressing flexible aluminium ducts to approx. 20 % of their length.

Maximum duct length 5 m

Nominal width: 50-650 mm

Video HST 650 A5

Mechanical engineering “Made in Germany”

Vacuum compression machine for flexible ducts

HAFLEX products for companies in the field of air-conditioning & ventilation technology

HVC 50/500 vacuum compression machine

a. For complete compression of flexible aluminium ducts of max. 5 m length and 50 – 150 mm diameter to 20 – 25 % of their initial length

b. For pre-compression of ducts with larger diameters of 160 – 500 mm to 30 – 50 % of their initial length

Video HVC 50/500

Automatic saw & vacuum compression machine video

Mechanical engineering “Made in Germany”

Pneumatic compression machine for flexible ducts

HAFLEX products for companies in the field of air-conditioning & ventilation technology

HPC 160/500 pneumatic compression machine

For complete compression of pipes, pre-compressed with the HVC 50/500, or short pipes up to 2 m in length and 160 – 500 mm in diameter. With strong pneumatic cylinder